The ubiquitous trucks we see on the highways are an integral part of our way of life. While not always pleasant to be around (or drive around), the $750 billion trucking industry provides the conveyance from one place to another of nearly everything we rely upon. evolveEA was recently asked to speak at the American Trucking Association's Technology and Maintenance Council's (TMC) semi-annual conference about sustainability in trucking. The Conference celebrated 60 years of influence as the trucking industry's primary trade group.

![tmc-evolveea-pitt-ohio]()

As with other industry trade group conferences at which we have presented, such as the Food Marketing Institute, we find an interesting interplay at work between the dominant industry trade group and the specter of government regulation. Industry trade groups are challenged with elevating the performance of their industries in palatable ways that stay ahead of potential government regulation. The balance between the ability to move the industry forward through incremental market forces while being responsive to larger demands from the public is a dynamic that advances nearly every industry that touches us.

![truck-expo]() The TMC was established in the wake the 1956 Interstate Highway Act to address the need for trucks to meet the durability and safety needs of this new infrastructure. Among the hundreds of exhibitors on the trade show floor were several forward-looking innovations that respond to government-driven aspirations. Diesel exhaust fluid (DEF) technology inserts urea into truck exhaust, changing the sooty nitrous oxides into inert nitrogen and water. Another innovation allows for truck tires to be continuously filled to mandated pressures even as the truck drives. And yet another innovation consists of panels around the truck wheels, improving gas mileage by .2mpg. All of these innovations and many more work together to create better-performing trucks that increase safety, comfort, efficiency and other improvements that the entire industry and public desire.

The TMC was established in the wake the 1956 Interstate Highway Act to address the need for trucks to meet the durability and safety needs of this new infrastructure. Among the hundreds of exhibitors on the trade show floor were several forward-looking innovations that respond to government-driven aspirations. Diesel exhaust fluid (DEF) technology inserts urea into truck exhaust, changing the sooty nitrous oxides into inert nitrogen and water. Another innovation allows for truck tires to be continuously filled to mandated pressures even as the truck drives. And yet another innovation consists of panels around the truck wheels, improving gas mileage by .2mpg. All of these innovations and many more work together to create better-performing trucks that increase safety, comfort, efficiency and other improvements that the entire industry and public desire.

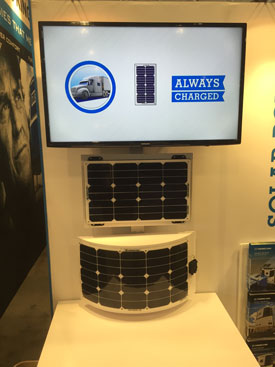

![solar-truck-exhibit]() Our Future Truck Session covered foreseeable innovations such as autonomous trucks, platooning, turbine motors, 3D sensor technology and data aggregation. We invited the Pitt Ohio trucking company to speak with us in describing their newly-opened office/terminal/maintenance facility in Harmar, PA. This 32 acre 96ksf complex has wind generation, a 60kw solar array, DC power integration, waterless fixtures, daylighting strategies, ground-coupled geothermal, radiant slab heating and bioretention areas with native plantings. The office and interior areas boast low emitting materials, CO2 sensors, ergonomic furniture and responsive HVAC in order to enhance the comfort of employees and visitors. We described the early goal-setting process facilitated by evolveEA at the outset of the project, which led to the integration of desired strategies into the project design. These early sessions, incorporating input from all Pitt Ohio top executives, set the tone for the Project and made their way into some of Pitt Ohio's overall building operations. We also described the adoption of LEED certification as a useful third-party structure for the desired strategies.

Our Future Truck Session covered foreseeable innovations such as autonomous trucks, platooning, turbine motors, 3D sensor technology and data aggregation. We invited the Pitt Ohio trucking company to speak with us in describing their newly-opened office/terminal/maintenance facility in Harmar, PA. This 32 acre 96ksf complex has wind generation, a 60kw solar array, DC power integration, waterless fixtures, daylighting strategies, ground-coupled geothermal, radiant slab heating and bioretention areas with native plantings. The office and interior areas boast low emitting materials, CO2 sensors, ergonomic furniture and responsive HVAC in order to enhance the comfort of employees and visitors. We described the early goal-setting process facilitated by evolveEA at the outset of the project, which led to the integration of desired strategies into the project design. These early sessions, incorporating input from all Pitt Ohio top executives, set the tone for the Project and made their way into some of Pitt Ohio's overall building operations. We also described the adoption of LEED certification as a useful third-party structure for the desired strategies.

As the Harmar project is occupied, we expect two LEED Gold certifications, which will be a first for the trucking industry. Ours was the first-ever TMC presentation addressing buildings and sites, rather than trucks and fleets. Given the positive feedback received from many of the over 500 attendees, we may be on to something.